AI Breakthrough Offers New Path to Designing Next-Gen Materials

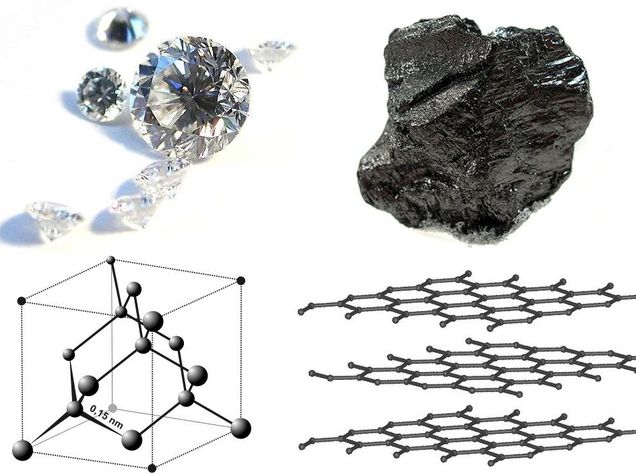

Every material’s properties—like strength or flexibility—depend entirely on how its atoms are arranged and bonded. Even with the same element, like carbon, small structural changes can lead to vastly different results: a diamond’s tight geometric bonds makes it hard, while graphite’s loose, layered structure makes it soft.

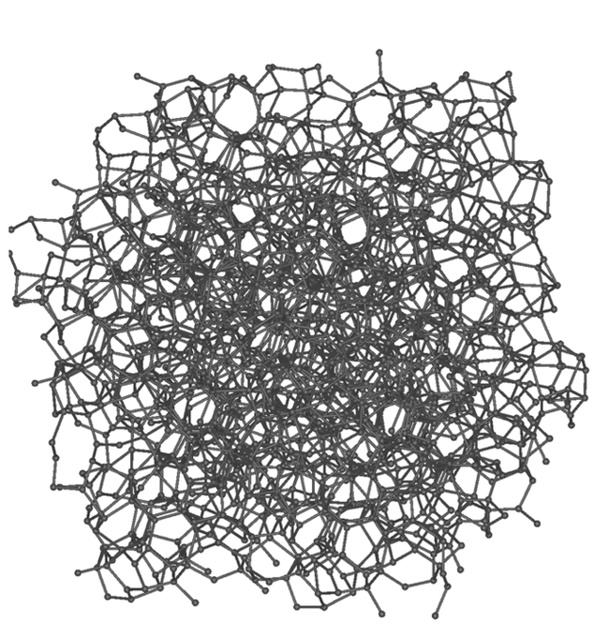

Amorphous carbon describes a carbon solid that has been altered via temperature and pressure to create a new disordered atomic arrangement. Depending on the new arrangement, the amorphous carbon can have new properties that make it ideal for today’s needs. For example, activated carbon and glassy carbon are two types of amorphous carbon that have different structures and properties. Activated carbon’s porous structure makes it great for water filtration, while glassy carbon’s tough and smooth structure makes it ideal for scientific equipment and batteries.

Creating a new amorphous material means discovering a new atomic pattern from scratch, a complex, unpredictable process that could take anywhere from 10 to 30 years — until now. A team that includes James Chapman, Assistant Professor of Mechanical Engineering and Hariri Institute Junior Faculty Fellow, has leveraged artificial intelligence (AI) models to catalyze the process of creating new materials such as amorphous carbon.

The work, a collaboration with Livermore Laboratory and recently published in Machine Learning: Science and Technology, could significantly speed up the discovery and development of new materials.

Why Do New Materials Take Decades to Create and Commercialize?

To design new glassy/amorphous materials (materials with no long-range atomic symmetry), scientists often melt a solid material down to disrupt the atomic arrangement. However, this often leaves a big question: What does the new atomic arrangement look like once a material is melted? Simulations can create the new material, but it’s a lengthy process to conduct and reproduce.

“The way it usually works is you start with the solid, heat it until it turns into a liquid, and then you cool it down in such a way that it retains the disordered state, but [the molecules] are not moving anymore,” said Chapman. “But you have to do that by taking every atom and updating its positions over and over and over again on the order of femtoseconds. So to give you an idea what a femtosecond is, there’s 10^15 of them every second. It’s a very complex simulation.”

While simulations can produce small-scale representations of the new material and its new atomic arrangement, commercialization requires large-scale production. To be useful in real-world applications, scientists need a way to scale that sample into a large material — a nearly impossible task using traditional methods alone.

How Artificial Intelligence Makes The Production of New Materials More Efficient

In their paper, Chapman and his collaborators combined their knowledge of materials science and AI to explore how to expedite the production of new materials. Since additional simulations take the most time, Chapman’s team looked to AI models to help visualize and scale new atomic arrangements without simulations.

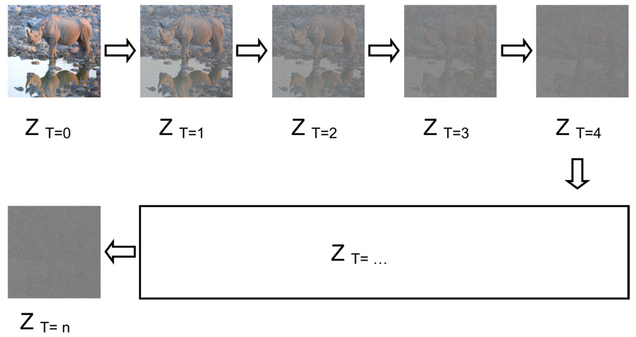

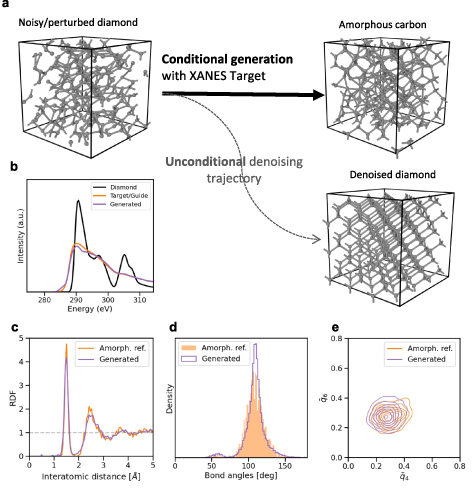

Diffusion models are AI models that drive randomness towards order by adding/removing noise to the data. They’re often seen in imaging editing software, such as OpenAI’s DALL-E. In the materials science domain, diffusion models have produced visualizations of new atomic arrangements. However, Chapman’s team took diffusion models a step further by adding a goal to the diffusion process, otherwise known as conditional diffusion, to increase the precision of these visualizations and eliminate the need for repeated simulations.

Chapman and his collaborators used X-ray Absorption Near Edge Structure (XANES) spectroscopy as the diffusion model’s goal for this study. XANES spectroscopy assigns a new material sample a profile based on its electromagnetic charge. Conditional diffusion models drive the system from randomness towards a structure with a specific XANES target.

“Let’s say I have two samples of amorphous carbon, carbon types whose atoms are arranged in a disordered way,” said Chapman. “One stores energy really well, and the other doesn’t but they look the same based on their XANES spectrum. You can’t distinguish their structural profiles. A conditional diffusion model could take that spectrum and generate a bunch of plausible atomic structures. This would give important insights into what types of structures can even get generated or represented from that spectrum, and then you can begin to analyze the actual differences in these structures.”

With conditional diffusion models, Chapman and his team were able to create a set of potential structures of amorphous carbon without running additional simulations — a process that would otherwise take incredible precision, time, and energy. This research opens the door to creating tomorrow’s new materials faster than ever before, such as environmentally-friendly batteries and more.

New Materials for Tomorrow

This research could revolutionize materials science. With AI models like these, scientists can more quickly design new materials for batteries, catalysts, and other critical technologies — potentially slashing development time from decades to just years.

“I think we’re entering a period where these algorithms will solve problems we once thought were impossible,” Chapman says. “We have massive amounts of data. There’s no reason to keep building narrow models when we can build general ones that help us discover almost any material we can imagine.”

Read more about Chapman’s research in IOPscience Machine Learning Science & Technology.