From Lab to Fab: How Analog Devices is Experimenting with a New Family of Products at BU

The Boston University Photonics Center is home to some of the finest on-campus business incubation facilities in the United States, including BU’s Business Innovation Center.

BY GARY RIVLIN

Mohamed Azize, a biomedical engineer and a senior manager at Analog Devices, the giant chip maker, had an idea for a new biomedical sensor that would improve home-testing for viruses. And he knew exactly where he wanted to set up a laboratory.

In 2009, Azize had visited the Boston University Photonics Center, located at 8 St. Mary’s Street, Boston. He had only recently arrived in the United States to start a post-graduate program at MIT and ventured to BU’s campus to meet with Theodore Moustakas, a professor (now emeritus) in the College of Engineering and a leader in the opto-electronics field. There, Azize caught a glimpse of his future when he laid his eyes on “the BIC”—the Business Innovation Center on the building’s sixth floor.

“There were all these startups, which really intrigued me,” Azize says. “Since then, I had in the back of my mind that one day I’m going to be at the BIC.” He would realize that dream a decade later when, in June of 2020, he set up a small Analog Device satellite in the BIC to work on a disruptive home and point-of-care diagnostic with the accuracy of a PCR test but the speed and low cost of an antigen test.

“They had this ecosystem perfect for developing and working on new technologies,” Azize says when explaining why a giant multinational would seek space inside a campus building. He also cited access to students and faculty and the dynamism of life on a campus, where he has a faculty appointment as an adjunct research assistant professor in the university’s Division of Material Sciences and Engineering. (Currently, he has one PhD student slated to graduate at the end of 2022.) The relationship has also proven beneficial to BU. Azize has granted internships to two BU engineering students since taking root at the BIC and Analog Devices has hired three BU graduate students since that time. A fourth, Azize said, is likely to join him at the BIC at the start of 2023.

The BICsters

BU’s Business Innovation Center is a business facility that occupies roughly 5,400 square feet inside the Photonics Center. Founded in 2005, the BIC provides cubicle, office, dry lab, and wet lab space. Tenants (called BICsters) also have access to the university’s core facilities around campus at a discounted rate.

Seventeen companies rented space in the BIC at the start of the 2022-23 academic year. A few are spinouts of ideas hatched on campus. Most are small startups spun out of other research institutions in the Boston area (among them, MIT, Harvard, and Massachusetts General Hospital) with no more than a few employees. By contrast, Analog Devices Inc., or ADI, has a workforce of 25,000 and cleared $11 billion in annual revenue, according to its most recent financial report. Onsite at the BIC, ADI has five full-time employees. Several other larger companies also rent space inside the BIC.

The “Lab to Fab” Model

Development and commercialization of new inventions is never easy, especially inside a large corporation, where priority is given to preserving the “golden goose” – the reliable revenue streams that keep everyone employed. Adding to the challenges is that the semi-conductors that ADI sells are stamped out in strictly controlled clean rooms using well-tested processes.

“There’s some natural reluctance to bringing in new materials that might cause compatibility issues, or adopting new techniques that cause problems,” Azize says. The company, based in Wilmington, Mass., created what it calls Analog Garage, a unit within the larger corporate structure created to drive innovation among ADI employees with an entrepreneurial mindset. It’s the Analog Garage where Azize went to work in 2019.

“The idea is to make it so people can be an entrepreneur inside the company,” Azize says. Many might dream of starting a company but there are great risks to pursuing your own idea in a field like digital health, where the research can stretch over years. Azize would be an “intrapreneur” – someone who brings an entrepreneur’s drive and commitment to a project but inside a much larger organization. When Azize pitched his idea for a better home test, the director of ADI’s biosensor group and senior vice president of Digital Health Care gave the project his blessings. In 2020, Azize and his nano team went to work for ADI’s Digital Health Care unit. With the pandemic, they began working on a low-cost, rapid test with PCR molecular accuracy for use at home and point-of-contact facilities, with the idea of helping reduce the burdens on an overwhelmed health care system.

“The BIC seemed the perfect place to pursue entrepreneurial activity,” Azize says. “It’s the kind of environment where you can develop new technologies with new materials and then start scaling up your technology before talking to the manufacturing people at your corporation. Not only can you show people that something’s doable but done at no risk to manufacturing.”

Azize calls it a “lab to fab” strategy (“fab” is a shortening for the fabrication facilities where semiconductor companies stamp out chips): he and his team can safely experiment on a product until it’s at that point where it can safely be created in a fab. “This is how you can accelerate innovation in the industry,” he says. That mindset, he continues, allows them to pursue a strategy that means reliance on low-cost materials for products that are scalable and compatible with existing manufacturing capabilities.

Disrupting the Diagnostics Sector

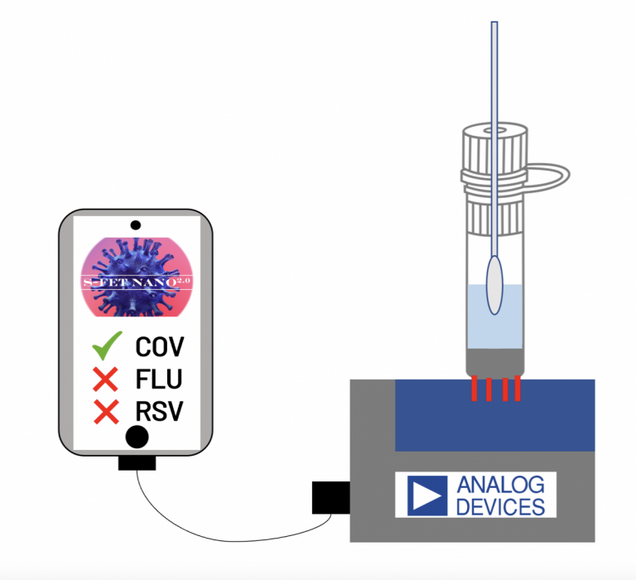

In the Photonics Center, Azize and his team occupy a couple of offices and a wet lab. There, they’re working on sensors that would allow people to self-test for common diseases. Because it was June of 2020, they began with a smart senor that could detect Covid. A sensor that could detect a coronavirus served as their test “use case”—a proof of concept for people back at headquarters. He and his team are working on sensors that can detect other viruses and eventually will move to bacteria-born illnesses: a biosensing, plug-and-play platform for quickly and effectively testing for infectious diseases.

“We’re trying to disrupt the landscape of diagnostics and move from centralized labs to more tests at home and at the point of care,” Azize says. “My vision is to develop a strong technology portfolio for at-home diagnostics.” His specs call for easy-to-use sensors that deliver fast and accurate results at an affordable price point. He and his nano team are also mindful of the environmental impact of whatever they create. They are aiming for a test that allows people to spit rather than take a sample from inside their nose. That would allow people to avoid that unpleasantness but also reduce the need for swabs and other consumables. “A technique that doesn’t require any tool would be awesome,” he says.

Azize confesses that they are not the most collegial of neighbors inside the BIC. “Being part of a corporation means protecting the IP [intellectual property] is always a top priority,” he says. Yet they still derive other benefits from working on campus. Anyone who’s part of the BIC gains access to conferences, symposia, and guest lectures, and even if they can’t share details of what they’re up to inside their lab, they’re exposed to others on campus conducting interesting research.

There are advantages as well to the university of Analog Devices’ presence on campus. Interns have worked on disposable nano-sensors that measure with molecular accuracy at the speed and cost of home and point-of-care antigen tests. Already three recent graduates from the engineering school have secured jobs at ADI’s headquarters in Wilmington. There have also been the company’s contributions to academic research on campus. “ADI is always looking to sponsor research that aligned with its interests,” Azize says. Toward that end, the company has a sponsored research agreement with Professor David Bishop, head of BU’s Division of Materials Science & Engineering, director of the school’s CELL-MET Engineering Research Center, and a pioneer in the detection of ultra-low magnetic fields for health care applications.

A little more than two years into his time at the BIC, Azize declares himself pleased with how things are going. “The value proposition I proposed said we would leverage this ‘lab to fab’ model to create product,” he says. “Today we are successful in a sense that we went all the way to a customer side to run real samples. Things are working as expected.

“We proved our point,” he says – and now the disruptive, diagnostic technology for molecular diagnostic application they’ve created is in the hands of higher-ups back in the company HQ. It’s now up to ADI’s business leaders to determine next steps.