The Hands-Off Approach

Densmore lab takes an important step to fully automate tedious procedures

By Liz Sheeley

Robots can get a bad rap when they are touted as the imminent revolution to replacing the labor force. But, when that labor force is comprised of biology research students performing repetitive tasks, automation can free up hours that can be redirected toward designing experiments and analyzing results, and important efforts such as writing research papers and grants. Associate Professor Douglas Densmore (ECE, BME), doctoral student Luis Ortiz (MCBB), Research Fellow Marilene Pavan (ECE), and software engineers Josh Timmons and Lloyd McCarthy from Lattice Automation (a software company Densmore co-founded) have demonstrated the usefulness of an automated pipetting robot paired with a novel software tool through a Journal of Visualized Experiments video.

Together they have developed the software component, mocloassembly.com, which allows researchers to compile a digital mock-up of genetic circuits that the automated pipetting machine then builds. The pipetting robot decreases the hands-on time of a tedious process like pipetting small volumes of liquid to set up 96 reactions from just over two hours to five minutes, and also increases reproducibility within the lab.

Ortiz says that mocloassembly.com generates all possible combinations of genetic circuits based on user-specified basic DNA parts, and allows researchers to compile large circuit libraries automatically. Their new software platform offers a very seamless pairing with the automated pipetting robot and is one of the only platforms that allows the user full control to customize the circuits and the robotic execution of the experiment. As genetic circuits are getting more complex and scientists want to test different iterations of a circuit that could have seven or eight components, the lab work becomes highly intricate, which increases the chance of human error and requires more hands-on time.

“Connecting software directly to bio-manufacturing processes is going to be increasingly important aspect of getting widespread adoption of software for engineering living systems,” says Densmore.

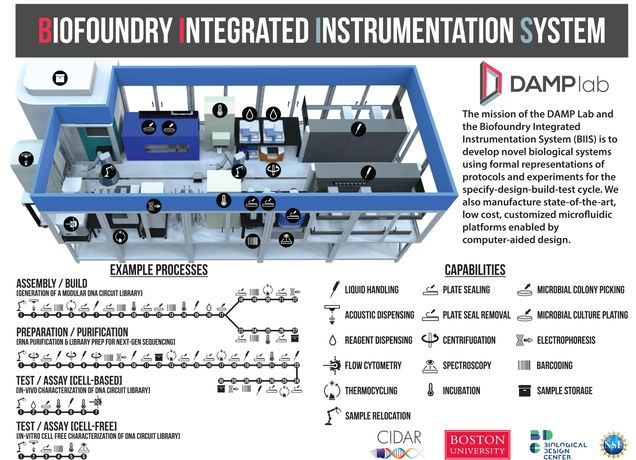

Ortiz, Pavan, and Densmore are envisioning a much larger automated system called the Biofoundry Integrated Instrumentation System (BIIS) to handle most of the work for a variety of experiments that would standardize lab protocols and increase reproducibility and repeatability. The team has submitted a National Science Foundation grant proposal to acquire funding to build the BIIS, which would be comprised of several devices that would allow for full automation of many molecular biology processes so almost no human involvement would be needed.

The current automated pipetting robot in Densmore’s lab is designed to handle larger transfer volumes of liquid than a typical manually prepared reaction, which means every experiment requires higher volumes of reagents than could be necessary. One of the machines that the BIIS proposal calls for is an acoustic dispenser, which uses the vibrations from sound waves to perform pipetting at a significantly smaller volume than the liquid-handling robot the team already uses.

The BIIS, in conjunction with software being developed in Densmore’s group, would allow full automation of the design, building, and testing of new biological systems driven by the creation of genetic circuits in significantly less hands-on time than the current process.