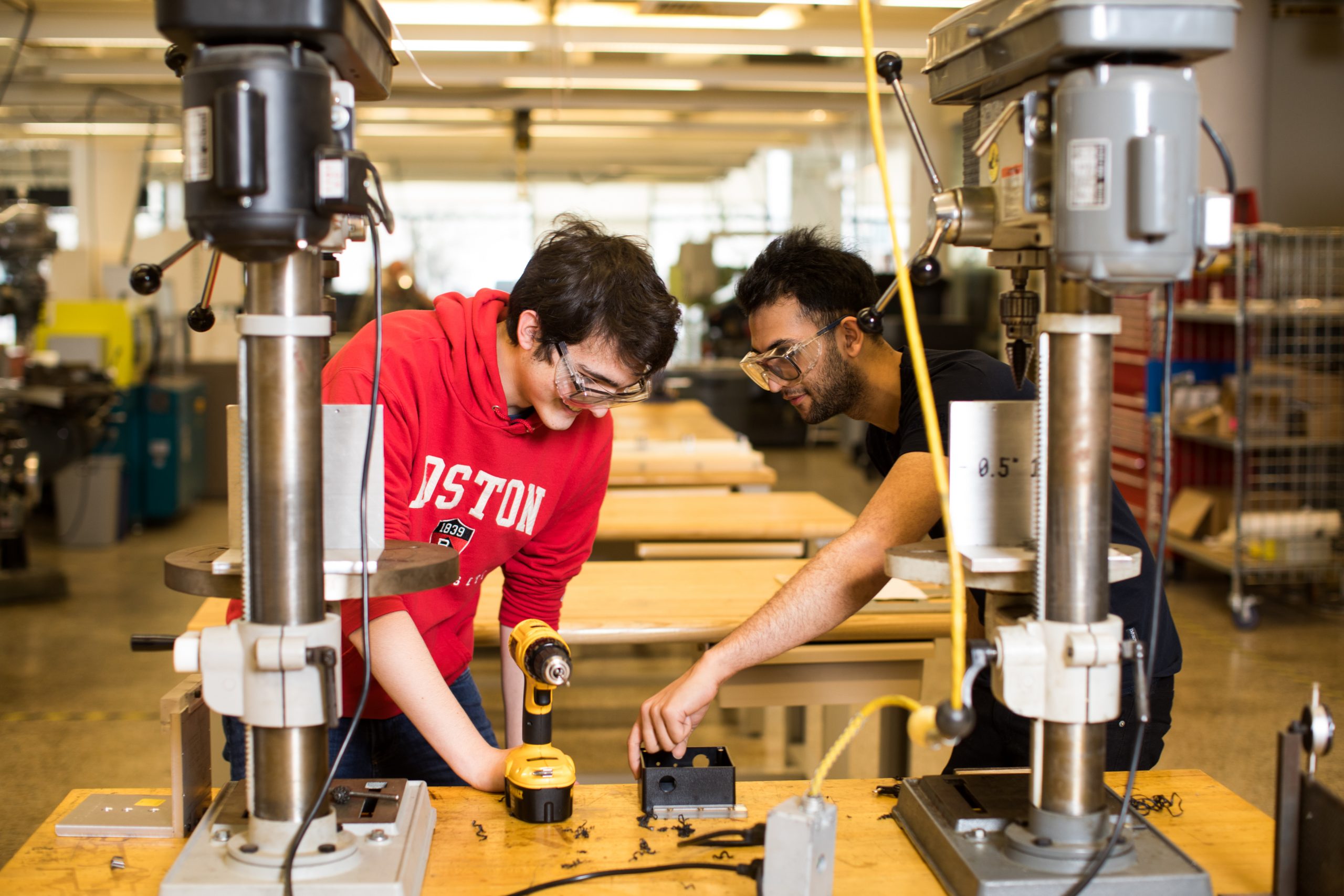

EPIC is an impressive 15,000-square-foot, multi-million dollar engineering, and manufacturing facility located in the heart of BU’s Charles River Campus.

Mission

Preparing students to work in and design for the industries of the future.

Enabling students to apply theory to real-world problems in both the virtual and physical space.

Provide a welcoming environment to foster innovation in interdisciplinary teams.

Engaging students, faculty, and industry partners to continually improve our offerings to meet our stakeholders' changing needs.

Preparing students to work in and design for the industries of the future.

Inspire all students to become future innovators in the fields of design and manufacturing.