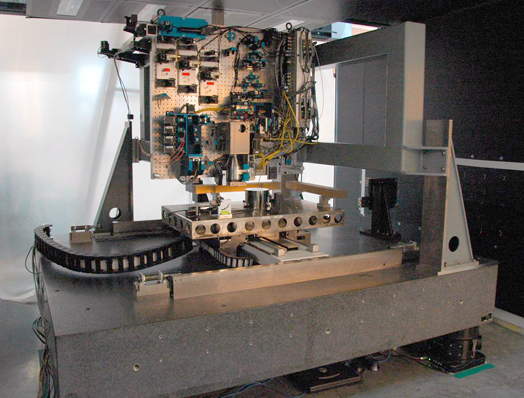

Large Scale Interference Lithography System

Fraunhofer CMI - Center for Manufacturing Innovation

- © Fraunhofer CMI.

Custom automation for high capacity, accurate diffraction grating production

Customer & partners:

In partnership with the Massachusetts Institute of Technology and an industrial customer, Fraunhofer CMI developed custom automation for the efficient manufacture of high accuracy, large scale diffraction gratings.

Technical summary:

Applications such as high power lasers used for Inertial Confinement Fusion research require gratings that cannot be produced via current semi-conductor manufacturing techniques. These gratings are nearly a meter in length by half meter in width, with closely placed lines, typically on a 400 nm to 1000 nm pitch, with a phase accuracy of 10 nm over the entire length. The newly developed custom automation system writes the lines by scanning an interference pattern of two UV laser beams over the optical substrate. A high speed metrology system optically steers the interference pattern to correct for errors in the mechanical motion of the scan to ensure accuracy. This metrology system makes extensive use of Zerodur and Super Invar components to maximize accuracy and stability.

Results:

- Constructed a high-performance system for large, interference lithography substrates

- Substrate dimensions:

1.0 m x 0.5 m

- Maximum load:

100 kilograms

- Diffraction grating periodicity:

0.2 - 5 micron

- Line placement accuracy:

2.5 nanometers over entire substrate - Temperature control precision:

±0.005 °C.

Further Information

Set Bookmark