Issue Archives

Bostonia is published in print three times a year and updated weekly on the web.

Summer 2018

Winter-Spring 2018

Fall 2017

Summer 2017

Winter-Spring 2017

Fall 2016

Summer 2016

Winter-Spring 2016

Fall 2015

Summer 2015

Winter-Spring 2015

Fall 2014

Summer 2014

Winter-Spring 2014

Fall 2013

Summer 2013

Winter-Spring 2013

Campaign 2012

Summer 2012

Winter-Spring 2012

Fall 2011

Summer 2011

Winter-Spring 2011

Fall 2010

Summer 2010

Winter-Spring 2010

Fall 2009

Summer 2009

Spring 2009

Winter 2009

Related Stories

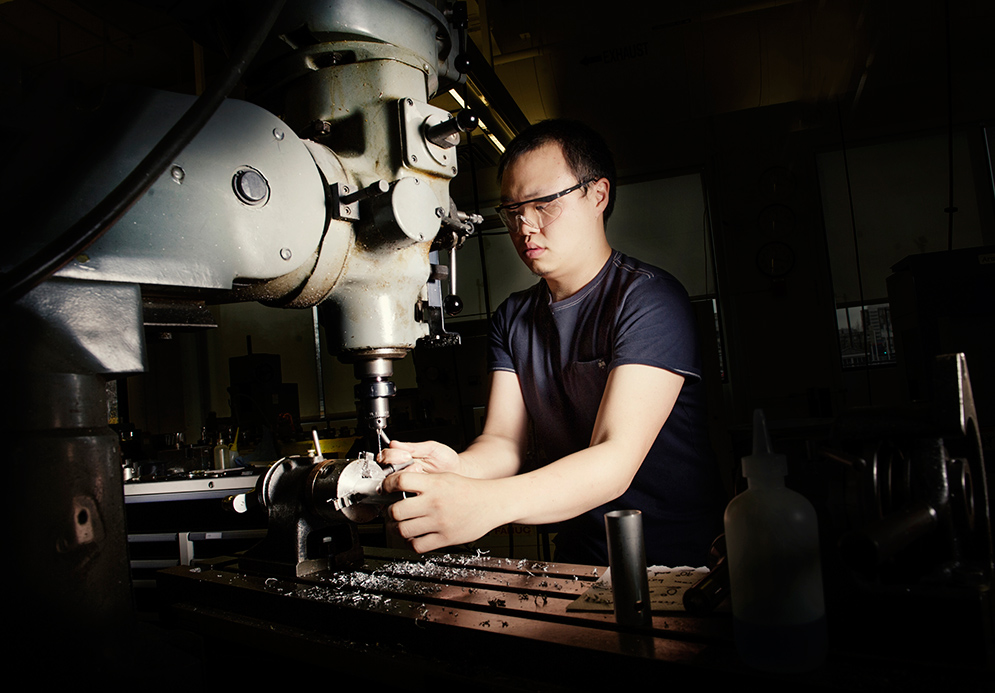

New EPIC Studio Will Equip ENG Students with Design Skills

$18.8 million in-kind gift helps transform engineering curriculum

EPIC Ribbon-Cutting Welcomes Industry, Local Officials

Features tour of ENG’s new design, manufacturing studio

Future Engineers Learn Real-life, Hands-on Design

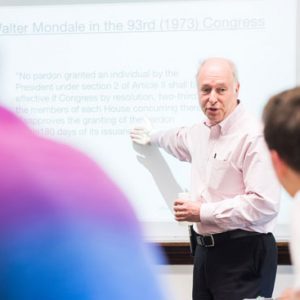

ENG’s Gerald Fine wins Gitner Award for classroom tech use

Post Your Comment