Arvind Agarwal

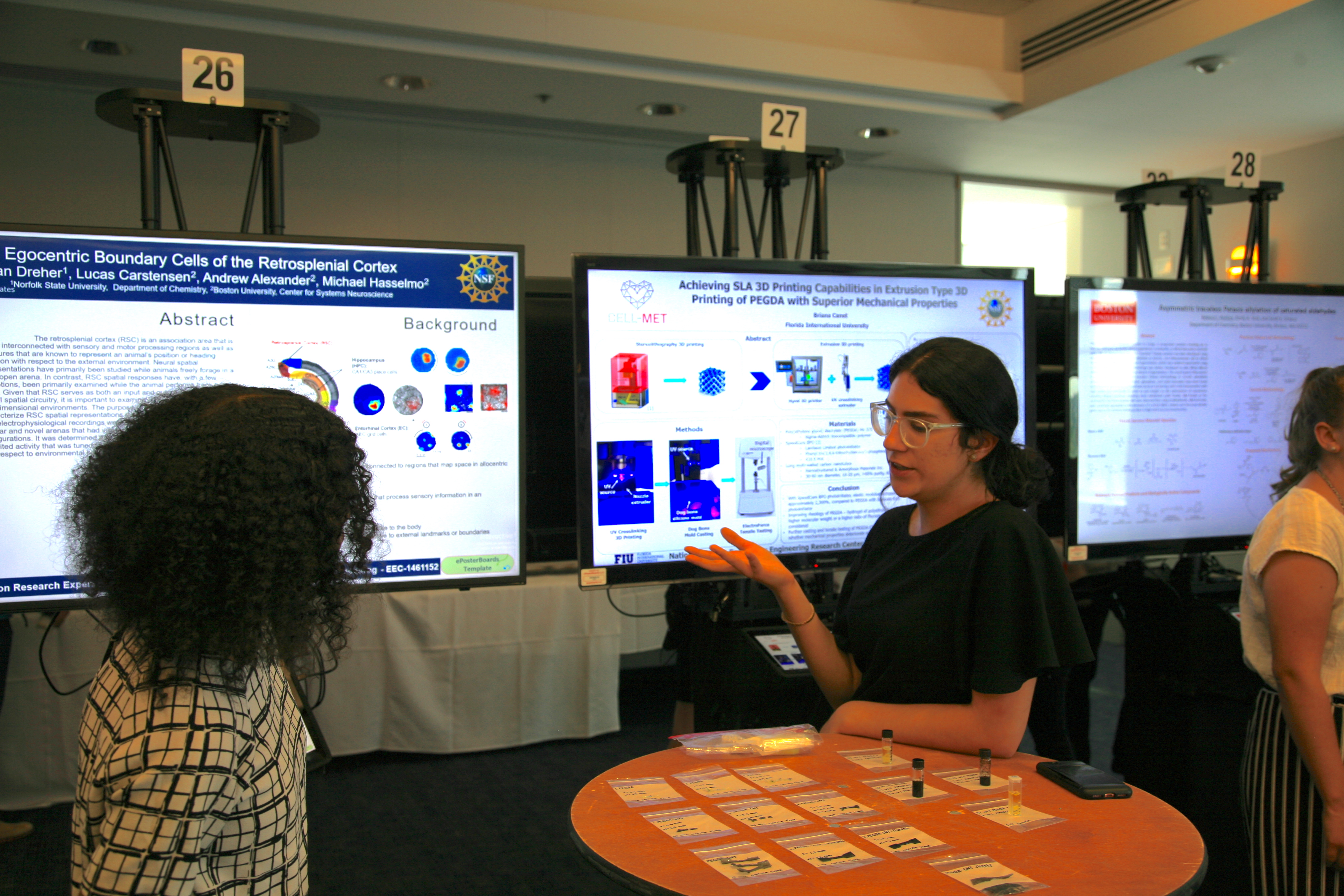

Achieving SLA 3D Printing Capabilities in Extrusion Type 3D Printing of PEGDA with Superior Mechanical Properties

ABSTRACT

The overall objective is to print micro scaffolds and micro lattices using UV crosslinking 3D extruder on a Hyrel 3D printer with PEGDA photo-polymer which is typically 3D printed using SLA printing technique. The specific objectives include improving the rheology of PEGDA for extrusion, optimizing printing parameters, improving mechanical properties of PEGDA by MWCNT addition, and evaluating the effect of MWCNT addition on the mechanical properties of PEGDA by mold casting dog bone structure.

CONCLUSION

With SpeedCure BPO photoinitiator, elastic modulus increased by approximately 2,300%, compared to PEGDA with Irgacure 819 photoinitiator. Improving rheology of PEGDA – hydrogel of polyethylene oxide of higher molecular weight or a higher ratio of Pluronic F-68 is considered. Further casting and tensile testing of PEGDA-CNT is needed to determine whether mechanical properties deteriorate with CNT addition

UNDERGRADUATE STUDENT

Briana Canet

GRADUATE STUDENT

Jenniffer Bustillos