Emulating Nature’s Patch Kit

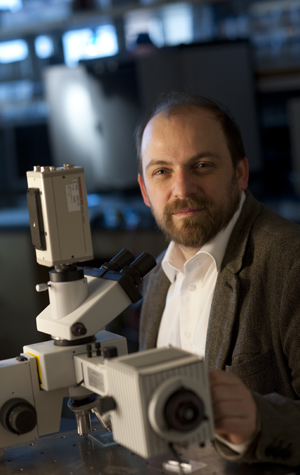

ENG researcher works on new ways to control fluidics

One of the myriad marvels of the human body is its response to injury, specifically the system that keeps us from bleeding to death from a cut, major or minor.

When a cut starts to bleed, a rapid, intricate process begins to patch things up. It’s a sequence of events that most of us take for granted, but the mechanics involved are so complex that they can seem magical. First, the breach of the blood vessel wall accelerates blood flow, which triggers the release of a specialized, coiled blood polymer—a chainlike protein comprising multiple repeating structural units—that unfolds into long strands. Next, these strands adhere to the blood vessel wall at the site of the injury, where they form a fibrous mesh. Finally, tiny components in the blood called platelets stick to the mesh, eventually filling all gaps between the strands. The result is a polymer-platelet composite that effectively “plugs the hole” where the skin was wounded.

To Matthias Schneider, a College of Engineering assistant professor of mechanical engineering, and Alfredo Alexander-Katz, an MIT professor of materials science and engineering, analyzing this process is much more than an academic exercise. Whereas most biological materials, from abalone shells to collarbones, form very slowly, blood clotting occurs remarkably quickly, quickly enough to serve as a possible model for the design of novel materials and medical devices.

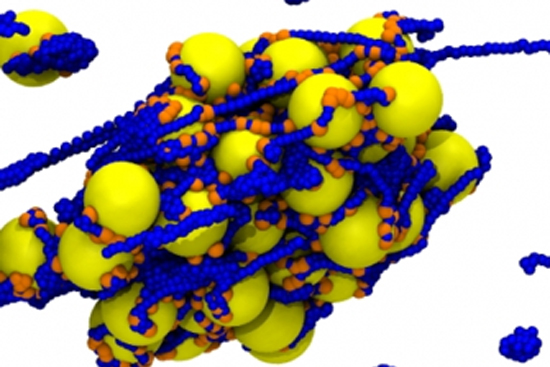

In a set of experiments conducted in his Biological Physics Lab, Schneider showed that the blood clotting process can be generalized to assemble synthetic composites that combine polymers with colloids, or microparticles dissolved in solution similar to platelets swimming in blood. At MIT, Alexander-Katz used computer simulations of Schneider’s findings to develop a theory explaining the composite formation process.

The results of the interdisciplinary collaboration, which were published in the January 8 online edition of Nature Communications, have important implications for the assembly of polymer-colloid composites. Developed by Schneider, Alexander-Katz, and six other researchers in the United States, Germany (including Schneider’s physician brother), and Austria with funding from the National Science Foundation and the German Research Foundation, the assembly process could be used to create novel composites with tunable mechanical, chemical, or optical properties.

“In any device with fluid flow and valves in narrow tubes, you run the risk of tubes getting jammed,” says Schneider. “Imagine you have to ‘clean’ a tube with a diameter less than that of a hair again and again to release the blockage. Our research suggests a protocol to design a material that self-assembles when needed and can be disassembled by a flash of light or ultrasound whenever, wherever, and how often you want. Devices equipped with such flexibility become more robust and therefore more reliable, which is particularly important for medical devices.”

Schneider and Alexander-Katz determined that based on the polymers selected, polymer-colloid composite materials within a fluid could be developed to combine—or fall apart—at a specific fluid flow rate, just as clots form and dissolve at a high and low blood flow rate, respectively. They also learned that the process could be paired with light to allow better control. By shining light at a particular frequency, the composite could be disassembled, an event that allows the same materials to be used over and over. The phenomenon could be applied to any device in which fluid flows, from kidney dialysis systems to instruments that dispense inks, pigments, and coatings to microfluidic diagnostic devices.

Mark Dwortzan can be reached at dwortzan@bu.edu.

A version of this article was originally published by the College of Engineering.

Comments & Discussion

Boston University moderates comments to facilitate an informed, substantive, civil conversation. Abusive, profane, self-promotional, misleading, incoherent or off-topic comments will be rejected. Moderators are staffed during regular business hours (EST) and can only accept comments written in English. Statistics or facts must include a citation or a link to the citation.