Shape Lab

Imagine trying to bring the irregularly shaped, cartoonesque objects from the pages of Dr. Seuss’ books to life. How would you do it? Curved, organic shapes and structures are difficult to create using traditional manufacturing methods—requiring the craftwork of designers, builders, or architects. But two Boston University computer scientists think that custom manufacturing should be more accessible to the average layperson. Now, they’ve combined computer science with a fabrication process known as fabric formwork, making it a whole lot easier to create large-scale custom shapes from scratch.

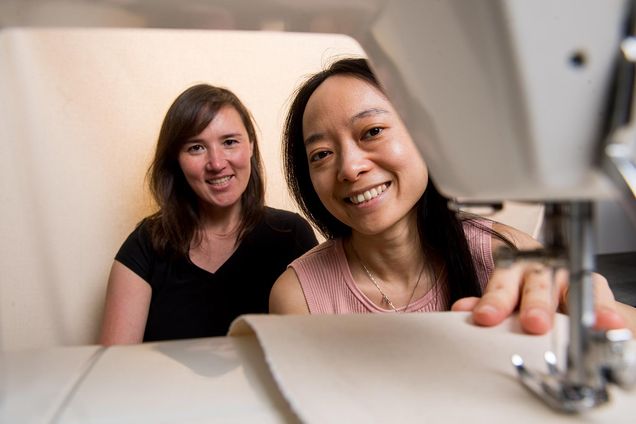

Emily Whiting, a BU College of Arts & Sciences assistant professor of computer science, and Xiaoting Zhang, a postdoctoral research fellow in Whiting’s lab, and collaborators from the Chinese University of Hong Kong, the National Institute for Research in Computer Science and Applied Mathematics (Inria), and Delft University of Technology, have developed a software algorithm that calculates how to cheaply and easily craft sculptural objects using just fabric, plaster, a sewing machine, and a little bit of patience. Their method makes use of the centuries-old technique of fabric formwork, which involves pouring casting fluid, like plaster or concrete, into a fabric casting mold that is suspended and supported by a rigid frame.

Articles: