|

|

||

|

|||

By Tim Stoddard

|

|

|

|

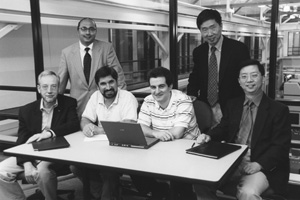

John Baillieul, Christos Cassandras, and Yannis Paschalidis (seated, from left) of ENG’s Center for Information Systems Engineering are developing sensor network control systems with far-reaching applications in manufacturing, homeland security, and space exploration. Their interdisciplinary team includes University of Massachusetts, Amherst, faculty Abhi Deshmukh, Weibo Gong (standing, from left), and Robert Gao (seated, far right). Photo by Fred Sway |

|

When an unbalanced washing machine starts dancing across the floor,

a sensor inside detects the wild gyrations and halts the spin cycle.

In the future, says Christos Cassandras, washing machines and other household

appliances will go a step further: they’ll call a repairman before

a part breaks.

Cassandras, an ENG professor of manufacturing engineering,

says that appliances will be only one of many applications for so-called

sensor

networks, which feature a constellation of miniature devices that monitor

a wide range of things, from vibrations to temperature to toxic chemicals

and biological weapons. Cheap, lightweight, and built with tiny radios,

the sensors will talk to one another, coordinating

their reconnaissance and relaying their findings to a distant computer.

An aging washing machine, for example, might notify the manufacturer

of an imminent problem over a wireless Internet connection. The owner

might then receive an e-mail from the dealer to schedule a service visit

for a part that may not break for several weeks.

Sensor networks promise

to improve everything from manufacturing to homeland security to endangered

species management. But while the technology for

building tiny, cheap, and intelligent sensors is rapidly emerging, Cassandras

says, the challenge now is to develop theories for managing the flow

of information among hundreds or even thousands of networked sensors.

With an interdisciplinary team of engineers at ENG’s Center for

Information Systems Engineering (CISE), Cassandras and his colleagues

have received a prestigious award from the National Science Foundation’s

Division of Design, Manufacturing, and Industrial Innovation to develop

methods

of managing complex sensor networks.

With the award’s $2.5 million

over the next five years, the BU team will work with colleagues at the

University of Massachusetts, Amherst,

to design sensors that communicate with one another, learn on the job,

and tolerate extreme environments. The team includes Yannis Paschalidis,

an ENG associate professor of manufacturing engineering, David Castañon,

an ENG professor of electrical and computer engineering, and John Baillieul,

an ENG professor and chair of the department of aerospace and mechanical

engineering.

Initially, the CISE team will go to the chalkboard, hashing

out the theories and principles underlying sensor networks. “We’ll

be conceptualizing these new technologies and abstracting them to pictures,

equations, and

computer-based simulations,” Cassandras says. “One of our

main tasks is to develop algorithms — systematic and methodical

ways of doing something more efficiently — to make good decisions

and get this information and technology to people who can implement it.”

Down

the road, members of the team will also develop a test bed at BU to experiment

with sensor network designs. To start, however, the UMass

faculty will be principally involved in building and testing sensor hardware.

Researchers there have been designing ball bearings with tiny sensors

that monitor vibrations and send a wireless signal when the ball bearing

is breaking down and needs to be changed.

Repair thyself

The CISE team believes sensor networks

will play an important role in large-scale industrial settings. In factories,

for instance, sensors

will be embedded in tools and machines to identify problems before

they cause catastrophic failures. A variety of sensors could be used

to keep track of fuel and raw materials at every step of production,

says Paschalidis, providing a real-time inventory that would dramatically

improve planning and supply chain management. The smart washing machine

is an example of the potential for postmanufacturing product monitoring. “What

we’re headed for is a day in which products essentially will

repair themselves,” Baillieul says, “or communicate with

the factory about what’s gone wrong and what needs to be done.”

Locating

personnel and mobile equipment such as forklifts within an industrial

campus can be a major bottleneck to efficiency and safety, Cassandras

says. By tagging these mobile elements with radio frequency identification

tags (RFIDs), similar to the EZ-pass units used on the Massachusetts

Turnpike, companies would have a real-time map of the location of each

item. RFIDs are also expected to have a major impact in retail. Instead

of bar codes, items in the supermarket and department stores will have

tiny RFIDs that identify themselves to sensors on the shelves, giving

companies valuable real-time inventories.

The major challenge for the

CISE team will be integrating different kinds of information from sensors

that are built to monitor different things. “Computers

talk to each over the Internet,” Cassandras says. “That’s

fascinating, but relatively simple. What we’re dealing with in

sensor networks are heterogeneous devices that are taking qualitatively

different measurements at different rates. It’s not just the exchange

of information. There’s also the element of motion in the different

sensors, and the fact that they are essentially speaking different languages.”

As

the CISE team wrestles with the management of sensor networks, it is

prepared to adapt to the rapidly evolving sensor technologies that

will undoubtedly develop in the coming years. “As a group, we’ve

done a lot of work in other areas that are cutting edge,” says

Cassandras. “But this is really one situation where we don’t

know what’s going to happen in fundamental technology three years

down the line.”

For more information on CISE, visit www.bu.edu/systems or call 617-358-1295.

![]()

31 October

2003

Boston University

Office of University Relations