By Douglas Holmes

MSE Innovation Grant Winner

The MOSS lab was one of six MSE Innovation Grant Winners from the Materials Science Division at Boston University in 2017.

Science360: MOSS@BU

Science360 is highlighting some research from the Mechanics of Slender Structures lab at BU:

https://science360.gov/obj/video/7d008e3b-f075-4d6d-bd84-2b6433b1658f/mechanics-slender-structures

Paper: Elastogranular Buckling

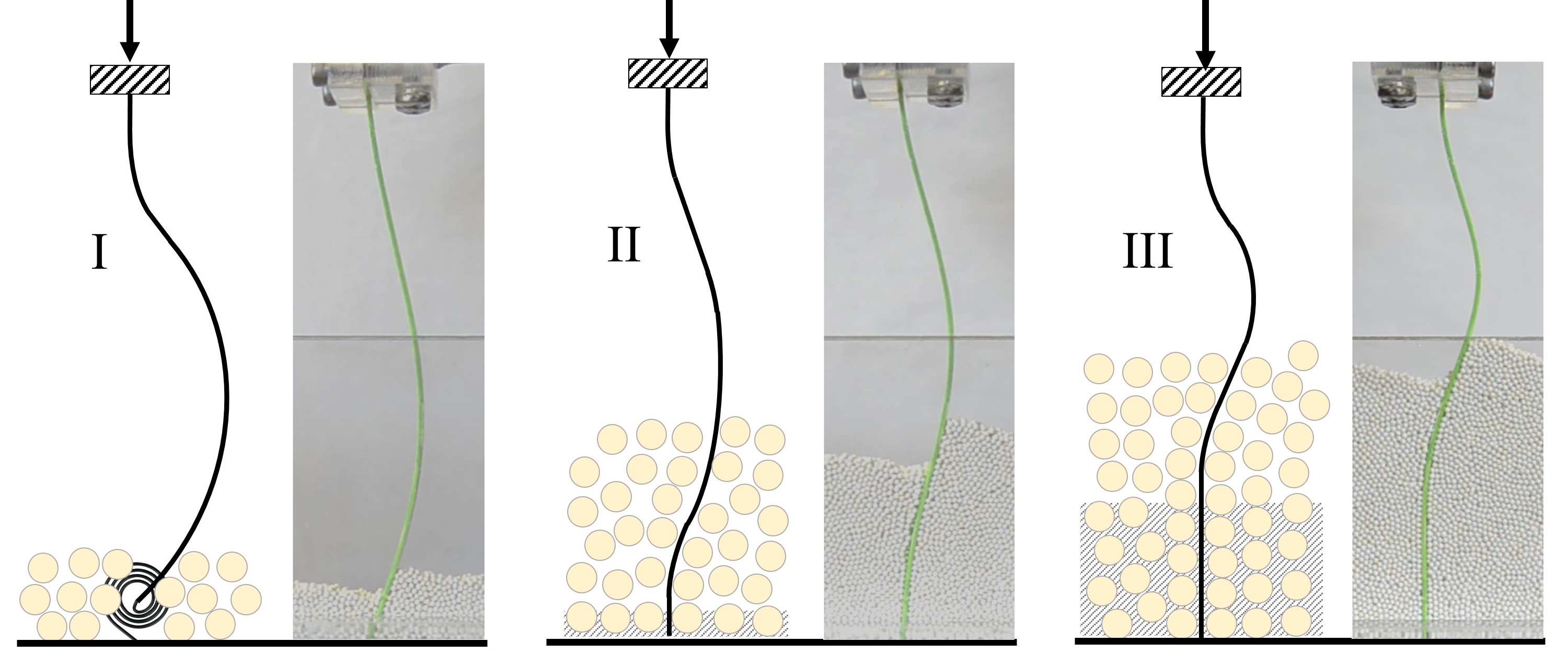

Buckling of elastic beams embedded in granular media

Ahmad R. Mojdehi, Behrouz Tavakol, Wesley Royston, David A. Dillard, Douglas P. Holmes, Extreme Mechanics Letters, 9, 237–244, (2016).

Abstract: In this paper, an experimental and theoretical study of the buckling response of slender elastic beams within granular media is performed. Buckling loads of beams with different flexural rigidity, length, and boundary conditions within granular media of different depths are determined. The Ritz approximate method is implemented to model the buckling response of the beams based on the concept of an overhanging beam on an elastic foundation, using a series of springs whose spring constants change linearly with respect to the depth of the grains. There is good agreement between the experimental results and the theoretical model. There is a characteristic penetration ratio where the beams are not able to sense the boundary condition at the embedded end, resulting in a convergence of the buckling loads. This condition happens when the rigidity of the beam is lower than the effective stiffness of granular support, leading to the confinement of the lower portion of the beam inside the grains, and acting as a secondary boundary condition that is independent of the condition at the end of the beam. We derive a scaling law to characterize this characteristic penetration ratio in terms of a dimensionless stiffness parameter, allowing for the characterization of three distinct interactions between the beam and medium based on the ratio of granular support effective stiffness to the beam’s effective stiffness.

Link: http://www.sciencedirect.com/science/article/pii/S2352431616300335

BU ENG: Elastocapillary Swelling

How the Baobab tree inspires swelling and morphing structures: https://t.co/CxDGtHFnUb - thanks to @SaraCody

— Douglas Holmes (@dpholmes) July 1, 2016

Read more at: http://www.bu.edu/phpbin/news-cms/news/?dept=666&id=63141

Twitter: Elastocapillary Swelling

What happens when you dip two rubber beams into a bath of oil? Something very bizarre... https://t.co/PRCuCOW6XH pic.twitter.com/JJpjI4mgqF

— Douglas Holmes (@dpholmes) June 1, 2016

Paper: Elastocapillary Swelling

Rising Beyond Elastocapillarity

Douglas P. Holmes, P.-T. Brun, Anupam Pandey, and Suzie Protière, Soft Matter, 12, 4886-4890, (2016).

Abstract: We consider the elastocapillary rise between swellable structures using a favorable solvent. We characterize the dynamic deformations and resulting equilibrium configurations for various beams. Our analysis reveals the importance of the spacing between the two beams, and the elastocapillary length, which prescribes the relative magnitude of surface tension and bending stiffness in the system. In particular, we rationalize the transition between coalescence-dominated, bending-dominated, and swelling-dominated regimes, and enumerate the subtle interfacial mechanisms at play in the ratcheting of a fluid droplet trapped between the curling beams.

Link: http://pubs.rsc.org/en/content/articlelanding/2016/sm/c6sm00329j#!divAbstract

Paper: Growing sheets into shells

Geometry and mechanics of thin growing bilayers

Matteo Pezzulla, Gabriel P. Smith, Paola Nardinocchi, and Douglas P. Holmes, Soft Matter, 12, 4435-4442, (2016).

Abstract: We investigate how thin sheets of arbitrary shapes morph under the isotropic in-plane expansion of their top surface, which may represent several stimuli such as nonuniform heating, local swelling and differential growth. Inspired by geometry, an analytical model is presented that rationalizes how the shape of the disk influences morphing, from the initial spherical bending to the final isometric limit. We introduce a new measure of slenderness that describes a sheet in terms of both thickness and plate shape. We find that the mean curvature of the isometric state is three fourths the natural curvature, which we verify by numerics and experiments. We finally investigate the emergence of a preferred direction of bending in the isometric state, guided by numerical analyses. The scalability of our model suggests that it is suitable to describe the morphing of sheets spanning several orders of magnitude.

Link: http://pubs.rsc.org/en/content/articlelanding/2016/sm/c6sm00246c#!divAbstract

arXiv: http://arxiv.org/abs/1509.05259

Faculty Profile: Douglas Holmes

A faculty profile of Douglas Holmes, written by Rachel Riley, for BU's Department of Mechanical Engineering: http://www.bu.edu/me/faculty-profile-douglas-holmes/

Paper: Buckling with fluid electrodes

Voltage-induced buckling of dielectric films using fluid electrodes

B. Tavakol and D.P. Holmes, Appl. Phys. Lett., 108, 112901, (2016).

Abstract: Accurate and integrable control of different flows within microfluidic channels is crucial for further development of lab-on-a-chip and fully integrated adaptable structures. Here, we introduce a flexible microactuator that buckles at a high deformation rate and alters the downstream fluid flow. The microactuator consists of a confined, thin, dielectric film that buckles into the microfluidic channel when exposed to voltage supplied through conductive fluid electrodes. We estimate the critical buckling voltage and characterize the buckled shape of the actuator. Finally, we investigate the effects of frequency, flow rate, and pressure differences on the behavior of the buckling structure and the resulting fluid flow. These results demonstrate that the voltage-induced buckling of embedded microstructures using fluid electrodes provides a means for high speed, repeatable attenuation of microfluidic flow.

Link: http://scitation.aip.org/content/aip/journal/apl/108/11/10.1063/1.4944331

arXiv: http://arxiv.org/abs/1601.02866

Video: https://vimeo.com/159996841