Agarwal Lab

Arvind Agarwal is a Distinguished University professor in the Department of Mechanical and Materials Engineering at Florida International University. He received his PhD in materials sciences and engineering from the University of Tennessee.

Prof. Agarwal’s lab seeks to study advanced material processing, cold spray, thermal spray, spark plasma sintering, ultrahigh temperature ceramics.

Participants

Projects

Learning from Nature: Mechanics of Mimosa Pudica and its Enlightenment in Vascular Scaffold Designing (2023)

PROJECT DESCRIPTION

Mimosa Pudica is a legume family plant with hypersensitive leaves that could fold inward in response to external force, which is called seismonastic movement for defense or nutrient maintenance. Its force-sensitive mechanism is due to curved structure and electrical-chemical signaling. Mimicking the reversible curvature, a 3D metallic glass structure with buckling ability was designed (Li et al., 2022). Enlightened by this automatic shrinkage and expansion function, researchers are working on designing 3D shape memory materials as vessel scaffolds and microelectromechanical bioelectronics due to their adaptable stiffness/flexibility to accommodate body movements and high durability and resistance to fatigues. However, there is a lack of fundamental understanding of the force mechanism to trigger seismonastic movement of Mimosa Pudica and its potential applications in cardiac bioengineering. Therefore, we aim to explore the mechanical response of Mimosa Pudica and its potential benefit for CELL-MET in manufacturing implantable and vascularized cardiac patches.

We aim to trigger Mimosa Pudica seismonastic movement using the nanoindentation probe with a defined load of nN – mN and record the force-response curves and leaf motion videos. Additionally, we will study leaf structure and structural-mechanical associations. Together with Lihua Lou, a research associate at Dr. Arvind Agarwal’s lab, the REU student will help with experiment design/setup, data recording/analysis, and reports. The specific research goals were to:

1. Understand Mimosa Pudica seismonastic movement mechanism. How does it happen?

2. Learning about nanoindentation technique. What is the lowest force to trigger Mimosa Pudica seismonastic movement? What is nanoindentation technique and its advantages? How to use it?

3. Learning from nature: What can we learn from Mimosa Pudica? The association between the mechanical response of Mimosa Pudica and vessel scaffolds.

LAB EXPERIENCE

Research question, hypothesis, experimental design, data recording/analysis, and lab report. Nanoindentation technique: learn the basic concept of nanoindentation and equipment composition; learn the application of nanoindentation technique in soft material mechanical property measurement. Cardiac engineering: learn basic cardiac engineering tasks, the importance of biomechanics, and biomechanics measurement. Biomimetic design: learn biomimetic structure and functions; study the behavior of living systems can provide insights into sophisticated functions effectively and inspire the development of novel tissue-engineered constructs.

LABORATORY MENTOR

Lihua Lou

TIMELINE

Weeks 1 – 2: Orientation, safety training, literature review of Mimosa Pudica seismonastic movement mechanism.

Weeks 3 – 4: learn the basic concept of nanoindentation; observe Mimosa Pudica seismonastic movement; experiment setup, design, and trial test.

Weeks 5 – 9: study leaf force-response, structure, and structural-mechanical associations.

Week 10: Data analysis and prepare final presentation slides.

Printing of Soft Polymers (2019)

PROJECT DESCRIPTION

This project focused on developing syringe based 3D printing techniques for polymeric scaffolds. Through this process REU students learned about the correlation between printing (processing), polymer chemistry, and properties. The specific research goals were to:

1. Identify optimum printing conditions

2. Identify optimum polymer for printing scaffolds

3. Study the mechanical properties of the scaffold

LABORATORY MENTOR

Dr. Tony Thomas

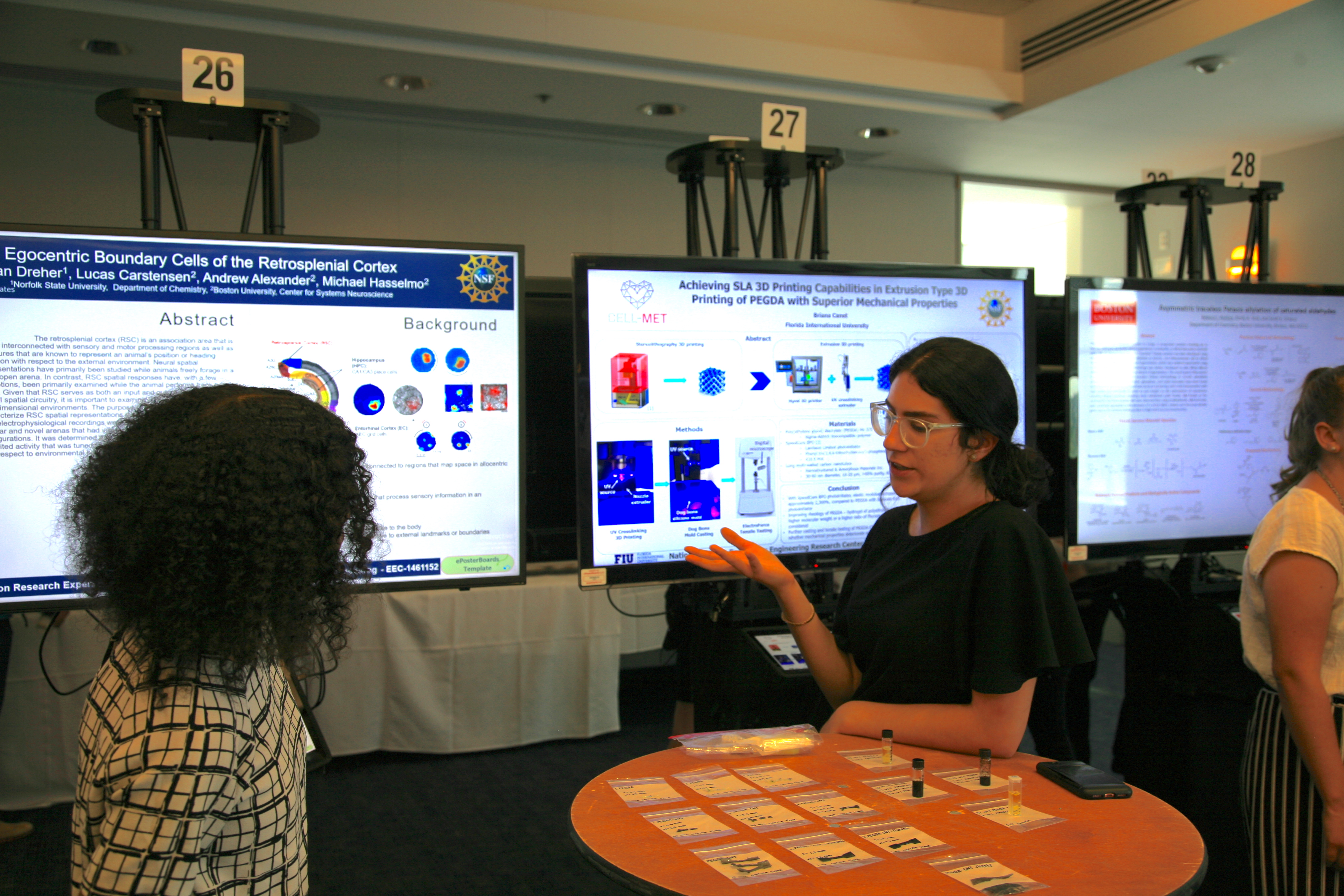

Achieving SLA 3D Printing Capabilities in Extrusion Type 3D Printing of PEGDA with Superior Mechanical Properties (2018)

ABSTRACT

The overall objective is to print micro scaffolds and micro lattices using UV crosslinking 3D extruder on a Hyrel 3D printer with PEGDA photo-polymer which is typically 3D printed using SLA printing technique. The specific objectives include improving the rheology of PEGDA for extrusion, optimizing printing parameters, improving mechanical properties of PEGDA by MWCNT addition, and evaluating the effect of MWCNT addition on the mechanical properties of PEGDA by mold casting dog bone structure.

CONCLUSION

With SpeedCure BPO photoinitiator, elastic modulus increased by approximately 2,300%, compared to PEGDA with Irgacure 819 photoinitiator. Improving rheology of PEGDA – hydrogel of polyethylene oxide of higher molecular weight or a higher ratio of Pluronic F-68 is considered. Further casting and tensile testing of PEGDA-CNT is needed to determine whether mechanical properties deteriorate with CNT addition