$12.1M

to build A state–of–the–art Manufacturing + Design Space for the entire BU Community

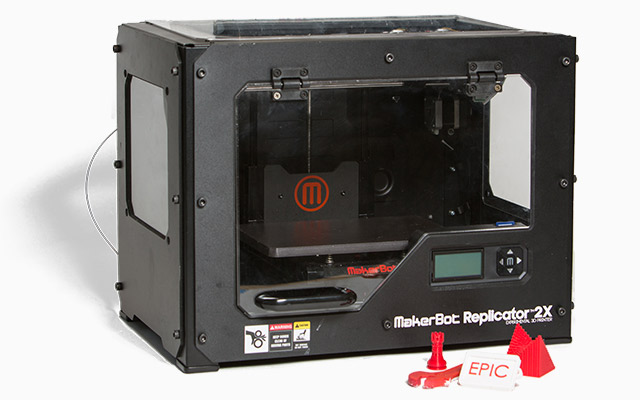

Last year, we threw open the doors to our new, cutting-edge Engineering Product Innovation Center (EPIC)—not only to BU’s engineering and manufacturing students, but to the entire community. Open 24/7, the 15,000-square-foot center offers a wealth of resources: computer-aided manufacturing technology, 3D printers, laser processors, a robotic assembly line, metal foundry, carpentry shop, materials lab, and a variety of machining tools—such as lathes, milling machines, and good-old-fashioned drills and saws. Positioning our graduates for the evolving job market, one of our industry partners, PTC, made a $18.8M in-kind gift of product design and lifecycle management software that is currently used by 27,000 manufacturers worldwide. But builders, inventors, and hackathoners aren’t the only ones flocking to the glass-fronted building on Commonwealth Avenue. BU’s sculptors and kinetic artists have been swooning over the 3D printers and laser cutters, too. “The mantra is interdisciplinary,” says EPIC Director Gerald Fine. “It’s only when you work in the cracks between disciplines that you really innovate.”

Open

24/7

To students

across campus

from engineering

to the arts

Tim Jackman (ENG'15)

Jackman, a PhD candidate in ENG, is building a device to carry out experiments on how bones in the spine get damaged through normal use.

Taylor Mortell (CFA'16)

Mortell, a sophomore at the College of Fine Arts, tapped the engineering expertise at EPIC, along with one of its laser cutters, to create a kinetic sculpture.

Hacking It

EPIC has hosted several all-night hackathons, where students write a lot of code or design products all night. It's about the joy of the process. And team-based work. One hackathon led to 10 mobile apps being created for 10 local nonprofits.

15,000 Square Feet

A robotic assembly line teaches students about manufacturing

From tried and true to cutting edge

This modern-day machine shop boasts a wealth of resources, from 3D printers and laser processors to a variety of machining tools—such as lathes, millers, and good-old-fashioned drills and saws.

Taylor Mortell (CFA’16)

Last Spring, inspired by Dutch kinetic artist Theo Jansen’s self-propelling beach creatures, sophomore Taylor Mortell was determined to create a time-based sculpture. So, sketch in hand, she took a left out of the College of Fine Arts building and headed down to EPIC.

“I worked with the engineering students to draw up the parts,” Mortell says. “I described what I wanted and they put it into the computer and showed me how to use the laser cutter. The motion of the sculpture was supposed to resemble a spider snatching an insect that was tangled up underneath it. It ended up looking really cool.”

Also cool, Mortell says, was the disciplinary cross-pollination.

“It was really interesting to talk with the engineering students. We discussed the applications of mechanical engineering and they were interested to hear how we were using some of their principles to enhance our sculptures.”

Explore Epic

Car dealership gives way to machine shop

Epic: Call it a Comeback!

By many accounts, manufacturing is making a comeback in the United States. As more and more jobs materialize, our College of Engineering graduates will leave BU with a distinct edge, thanks to a transformed curriculum, the latest industry software and technology at EPIC, and an emphasis on interdisciplinary learning. All engineering students, regardless of major, will now graduate with a thorough understanding of how to develop sustainable new products, from concept and design through manufacturing and delivery. That’s what we call training.

Applying Pressure

Doctoral candidate Tim Jackman (ENG’15) knew the answer to preventing a common back injury—wedge fractures that typically result from heavy lifting—lay in calculating the stress human vertebrae could withstand. So from his workstation at the Orthopædic & Developmental Biomechanics Lab, he reached out to the folks at EPIC. Starting with sketches on paper, Jackman and a staffer at the new manufacturing studio created a tube with a screw-top that could exert pressure until the vertebrae crushed. But the cup had to be made of durable material that wouldn’t show up on x-rays. Fortunately, “most of the design challenges were overcome by the people at EPIC,” Jackman said. After compiling the data from his experiments, he hopes to create computer models to “identify people who would be at immediate risk for fractures and do some intervention rather than treat them later after they have already fractured their spine.”

Dirty Fingernails And Elbow Grease: Undergraduate Research In 2014

Hands-on creation and research isn’t just happening at EPIC. All over campus, students are taking advantage of opportunities to get their hands dirty. In 2013/2014, BU invested some $1M in the Undergraduate Research Opportunities Program.

Here are just a few of the returns:

- Emily Lam (ENG’16) worked with Dr. Thomas Little on methods to improve and economize artificial lighting systems. For example, she investigated how to create “Smart Rooms,” where lighting will adapt and move to individuals in the room.

- John Aleman (ENG’14), who’s very involved with the Unmanned Aerial Vehicles (UAV) Team, worked with Assistant Professor Mac Schwager on “Aggressive Outdoor Maneuvers for Quad-Copters Using Multi-Rate Sensor Fusion.”

- Maureen Ogamba (SAR’14) teamed up with Assistant Professor Cara Lewis to study hip pain during pregnancy.

- Wanlu “Lulu” Xu (CAS’15, SAR’15) is helping design a DNA aptamer for the tuberculosis drug Isoniazid, which will be used in PharmaChk, a microchip that can detect counterfeit drugs in developing countries.

- Jeremy Wernick (CAS’14), a psychology major, tackled two research projects related to hoarding.

- Julian Tantzen (CAS’14) researched 550 renewable energy companies across the country and compared the efficiency of states with and without renewable energy standards. He presented his results at a conference.