Taking in the Trash

By Patrick L. Kennedy

It’s a kind of vessel where different ingredients are combined. The resulting broth percolates and, in time, produces a solution to a societal problem, whether the product is a line of cells that kill cancer, bacteria that decontaminate water, or plant-derived alternatives to petroleum-based plastics and fuels.

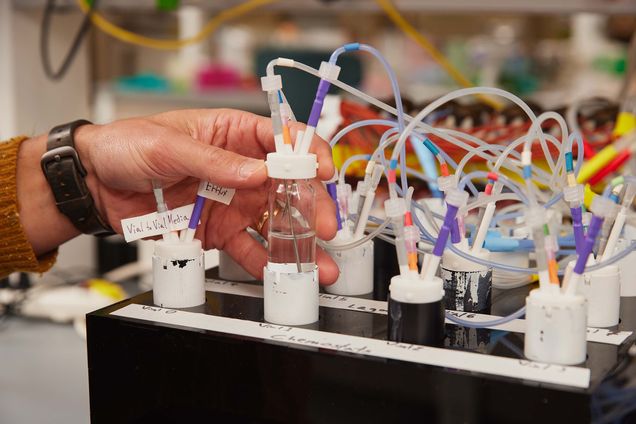

That description fits an actual container system called a bioreactor—and it’s a fair picture of the convergent approach in synthetic biology. In a bioreactor, the ingredients are cells and nutrients—for example, the byproducts of food scraps. In a convergent—that is, collaborative and cross-disciplinary—project, the ingredients are ideas and expertise.

So perhaps it is no surprise that, as part of a federal push for more and better bioreactors, the Boston University College of Engineering has been tapped for help. Because at ENG, convergence is the way things are done. Arguably, the college’s synthetic biology research is exhibit A.

Moving Beyond Fossil Fuels

A bioreactor is a key component of biomanufacturing. Instead of smokestacks pumping toxins into the atmosphere, biomanufacturing makes use of naturally occurring microorganisms and processes to make things—not just medicines and gene therapies, but also cleaner and greener materials, machine oils, detergents, fuels, fabrics, fragrances and even foods. It has the potential to revolutionize industry while dramatically cutting carbon emissions.

But, to realize that vision, biomanufacturing needs to be scaled up. In the United States in particular, the sector needs to grow significantly if we’re to avoid supply chain disruptions and security breaches.

That’s why Schmidt Futures has awarded a $3 million grant to a team of researchers from ENG, Capra Biosciences, Inc. and other collaborators to make a smarter, more efficient bioreactor. From ENG, the project is led by Assistant Professor Rabia Yazicigil (ECE), Professor Douglas Densmore (ECE, BME) and Associate Professor Ahmad “Mo” Khalil (BME).

Rabia Yazicigil (ECE), Mo Khalil (BME) and Doug Densmore (ECE, BME) are collaborating on a secure, efficient and replicable bioreactor. Dana J. Quigley Photography

The public, private and academic entities involved are part of a consortium called BioIndustrial Manufacturing and Design Ecosystem (BioMADE), which is aimed at making domestic biomanufacturing safe, sustainable and economically viable. Khalil, Yazicigil and Densmore are working with Capra Biosciences to refine and replicate the startup’s reactor technology on a grand scale.

Capra has developed a new kind of continuous flow bioreactor using biofilm, essentially a layer of slime hospitable to bacteria. The goal is to produce cosmetics, as well as lubricants for motors and other machinery, from biological rather than petrochemical sources. “We want to engineer organisms to help us make products sustainably and cost-competitively,” says Capra cofounder Andrew Magyar, “so consumers won’t have to decide, ‘Do I want the sustainable option or the cheap option?’”

“We want to engineer organisms to help us make products sustainably and cost-competitively.”

Making the business feasible will require automation and novel quality-control and security measures. The trio from BU—combining their backgrounds in genetic engineering, electronics and automation—has proposed an innovative bioreactor design that checks all those boxes.

“This kind of convergence of disciplines is amazing,” says Magyar. “It is the future in terms of where advances in biotechnology are coming from, and BU is definitely at the forefront.”

A Technology Evolves

Khalil began his career as a mechanical engineer, but today he is better known as a pioneer of synthetic biology. In particular, Khalil’s team builds molecular “circuits,” and they have translated these insights into gene circuit engineering platforms that enable the programming of human cells, such as immune cells, for a new generation of cellular therapies that might one day be used to combat diseases such as cancer.

“We like to ask the simple yet bold questions, ‘What if we built it?’ and ‘What can we learn from this process?’” says Khalil. “That inverse approach to the study of biology forces one to question prevailing assumptions, and it can lead to surprising results.”

Capra especially wanted to work with Khalil because he’s developed a small-scale bioreactor system called eVOLVER, now in use in more than 50 universities. A customizable, automated platform that can remotely monitor and manage hundreds of cell cultures in real time for a variety of applications, this DIY open-source system is infinitely adaptable, allowing researchers to create custom automation tools for their own microbial experiments.

One of Capra’s objectives is to develop new methods for working with complex waste-based feedstocks—in other words, the material left over after bacteria break down manure and food scraps is what gets fed into a bioreactor—but a challenge with that kind of material is variability in its makeup. By running a slew of experiments with eVOLVER, Khalil will rapidly optimize the process, allowing different types of waste-based feedstocks to turn out a consistent level of product—in this case, retinol (vitamin A) to start with.

Khalil is adapting his invention to this work with a custom diffuser, precisely controlling fluid flow and culture conditions. “By the end of 18 months, we want to have a fully automated biofilm reactor pilot plant that can continuously produce more than one kilogram of vitamin A per day,” says Yazicigil, but that will entail two more key stages.

Safe and Sustainable Sensors

Yazicigil’s expertise is in electronics, but she is more than a dabbler in biology. Some of her recent work includes designing an ingestible capsule that monitors gut health with the aid of a tiny sensor that runs on ultra-low power.

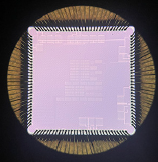

For the BioMADE project, Yazicigil is adapting that technology to produce sensors that will float inside the bioreactor and measure the levels of PH, oxygen, glycerol, lactate and various organic acids. The sensors will even evaluate the electric potential of the biofilm.

“Traditionally, bioreactors are monitored with bulky instruments or complex probes that have to be inserted in holes in the lid or side,” Yazicigil says. By contrast, her tiny sensors, running on mere nanowatt-level power, will wirelessly transmit the measurements in real time, allowing technicians to adjust the flow of nutrients as needed.

A crucial part of her task is making the communications secure, Yazicigil says, and her team is working with Capra to make security integral to the sensors. “We need to protect against communication attacks, like eavesdropping, or jamming attacks, which would impact communication between the sensors and the hub.”

“I have to tailor the sensor chips to fit the system needs of this bioreactor technology,” Yazicigil adds. “It’s an exciting project. It involves startups, academia, biomedical and electrical and computer engineering. It’s powerful to bring these all together.”

Democratizing Synthetic Biology

To truly scale up the modified eVOLVER, the operation will have to be moved to Densmore’s Design, Automation, Manufacturing and Processes (DAMP) Lab. An electrical engineer by training, Densmore has been working in synthetic biology research since 2007 and is a natural fit for the BioMADE project due to his expertise developing electrodes for microfluidics and robotics for high-throughput testing.

The DAMP Lab is an advanced biofoundry that did double duty for a couple of years as a major part of BU’s award-winning Clinical Testing Laboratory, which processed up to 6,000 COVID tests of faculty, staff and students per day during the pandemic. Now, the heavily automated lab is getting ready to run several biofilm-focused eVOLVER systems at once.

For Densmore, the product is not (or at least not only) retinol; it’s the process itself. By sharing the results, technical reports and methods of the BU team with the other 140 members of the BioMADE consortium, Densmore and company will be propagating a replicable system for converting all sorts of bio-based feedstocks into all manner of useful products.

Replicability is key, Densmore explains. “No one wants to say, ‘I cured cancer once.’” To tackle global challenges from cancer to climate change, he says, “We need more eyes on these problems. To do that, we need to lower the barrier to entry—but safely. So we centralize the manufacturing infrastructure,” within a certain number of certified labs like BU’s, “and distribute the computational infrastructure.”

First, BioMADE researchers will remotely order up experiments, and Densmore and team will carry them out. In the longer term, Densmore envisions members of the research community at large downloading the DAMP Lab’s software as well as the list of hardware used and assembly directions, so that other companies and universities can build their own bioreactors on the same model.

“That’s how we democratize biology with computing,” Densmore says. Instead of hoarding its “secret sauce” and running a unique “Michelin five-star restaurant,” as Densmore puts it, BU in a sense will franchise the DAMP Lab, standardizing equipment, software and processes all over the country. But, because BU’s eVOLVER-based, DAMP Lab–scaled bioreactor is infinitely adaptable, those replica labs won’t be producing identical studies and products. Other researchers will apply their creativity and generate their own solutions.

To use one more food analogy, Densmore points out that most people don’t bake their own bread, because it’s simply not an efficient use of their time. But, in biology, too much time is sunk into tasks that would be better automated and standardized, freeing researchers to use their minds.

“Pragmatically, that’s the only way to advance science and society,” Densmore says. “Right now, biology is baking a lot of bread.” By making BU’s packaged sliced bread available everywhere, “I’m saying, ‘Let’s get to making some cool sandwiches.’”