Visualization of Cuts for Computing Magnetic Scalar Potentials in Multiply-connected Regions by the Finite Element Method

P.W. Gross and P.R. Kotiuga

Department of Electrical and Computer Engineering

Boston University

E. Brisson and G.J. Bresnahan,

Scientific Computing and Visualization Group, Information Services & Technology Boston University

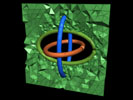

We demonstrate an algorithm to make “cuts” for magnetic scalar potentials in multiply-connected regions modeled by tetrahedral finite element meshes. For triangulations of knot complements, cuts are Seifert surfaces. In the context of magnetic scalar potentials, cuts are used to make the scalar potential single-valued, obviating typical vector methods and accelerating the computation of magnetic fields due to currents in the exterior of the tetrahedral mesh by a factor of ten in comparison to vector methods.

The algorithm results from a constructive proof that cuts, generators of the second relative homology group of the triangulated region modulo its boundary, are computable. The algorithm exploits the finite element method and any code necessary for cuts which cannot be found in a typical finite elements software package involves integer arithmetic so that no rounding error is introduced. For three-dimensional problems, the formulation via algebraic topology yields the most natural data structures and shows what is computable while avoiding pitfalls of topology which are trivial in two dimensions. (Hence the examples selected for this demonstration are intrinsically 3-dimensional.) Some properties of cuts shown in these examples include: distinct cuts may intersect, and cuts do not necessarily render the region simply-connected.

Our visualization allows the viewer to inspect the set of cuts associated with a multiply-connected region on an Immersadesk.

Video Sequence

We demonstrate results of an algorithm to make “cuts” for magnetic scalar potentials in multiply-connected regions modeled by tetrahedral finite element meshes. In the video, each ring of the Borromean rings (three rings which are unlinked but unseparable) and the exterior of the bounding box are regarded as current-carrying regions, and the cuts are made on the complementary (current-free) region which has been discretized. The cuts can be regarded as equipotential surfaces of the (multivalued) magnetic scalar potential due to each current. Two cut families (those for the orange and green rings) have only genus zero surfaces while that of the blue ring consists of genus one surfaces. In this example, any pair of cuts can be arranged to have zero intersection, but the third cut must intersect at least one of the first two — this is illustrated at the end of the video sequence.

A larger and slower 5.5 megabyte MPEG version is also available.

Still Images

Current-carrying Borromean rings inside a bounding box. Cuts are made on the region complementary to the rings. The green surface represents one cut from a family of cuts for the green ring, all of which are genus-zero surfaces.

A cut for the green ring shown as a 2-subskeleton of the tetrahedral mesh which models the Borromean ring complement (with the bounding box removed). The boundary of any cut is in the boundary of the mesh.

A cut for the brown ring shown as a 2-subskeleton of the Borromean ring complement discretization. This is close to a minimal surface area cut for the ring.

A cut for the blue ring shown without the bounding box. In this case, the cut has genus equal to one and the boundary of the cut is on every ring as well as on the bounding box.

Hardware: SGI Power Challenge Array and SGI Origin2000.

Software: C code and MATLAB. Visualization done in C, utilizing the IRIS Performer library and the CAVE libraries, on an Immersadesk.

Graphics programming and video production: Erik Brisson, Scientific Computing and Visualization Group, Boston University.

Acknowledgments: We gratefully acknowledge the National Science Foundation, International Division, and Hitachi Ltd., Central Research Laboratory, for supporting development and testing of the cuts code.