Nanoscale 3D Printing Enables Bioelectronic Medicine Research

When Professor Alice White (ME, MSE, Physics, BME) came to BU in 2013 as chair of Mechanical Engineering, she was keen to encourage the sort of cross-disciplinary research she had experienced as chief scientist at the storied Bell Labs. For her own research, she set up a powerful 3D-printing tool with nanoscale resolution—at the time, one of only three labs in the country with this tool. In addition to her personal projects, she hoped to attract collaborators whose research could be advanced using this capability.

An early realization of this hope came when, at the invitation of BU President Robert A. Brown, she gave a presentation to visitors from Singapore about her laboratory’s ability to design and print on such a small scale. Afterward, she was approached by Professor Timothy Gardner (Biology, BME), who had also presented, about his research challenge in measuring nerve activity in songbirds. Their collaboration blossomed quickly. The fruit of their collaboration, a nanoclip just twice the width of a human hair, is the focus of the cover article in the June issue of the Journal of Neural Engineering.

Gardner’s research team was working on experiments to stimulate and measure electrical activity in tiny nerves in zebra finches. But they found the attachment they used was too big and stiff for the delicate nerve, causing damage that led to inaccurate measurements.

“Professor Gardner mentioned how the current technology for attaching to the peripheral nerve in a zebra finch was cumbersome and caused damage and scarring,” said White. “We had a conversation in the morning about that challenge, came up with a solution, designed it that afternoon, printed it overnight and, the next morning, had the first version in Professor Gardner’s hands.”

“The nerve interface devices that are required to advance this emerging field must be very small, but also must be very securely attached to nerve for prolonged periods of time,” said Research Assistant Professor Timothy Otchy, “Though our lab had quite a bit of experience developing microelectrodes, we found that reliably making devices at that small of a scale was extremely challenging.” Otchy is managing Gardner’s laboratory while Gardner spends a year as one of the first employees in Elon Musk’s headline-grabbing new start up in this field, Neuralink.

Birdsong is not only an important avian communication tool, it also provides a reliable platform to study nerve damage because of its high sensitivity to change and the easily quantifiable outputs it produces. One of the areas Gardner focuses his research on is the emerging field of bioelectronic medicine, or controlling nerves by blocking or stimulating signals, which could provide a better alternative to treat a variety of diseases, such as rheumatoid arthritis, chronic pain and many others.

Charles Lissandrello, (ME’09,’12,’15), working as a postdoctoral associate in White’s laboratory, spearheaded the design of the device, working in tandem with Gardner’s research team. Two initial designs proved ineffective or unwieldy, but the third design was successful.

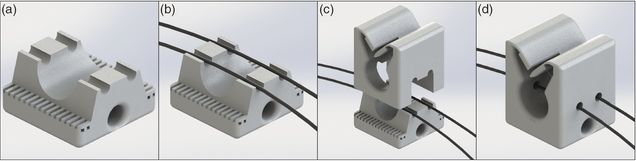

“The design described in our paper had two ‘trap doors’ with flexible hinges that would allow the nerve to pass through and lock the nerve inside, with a semi-cylindrical interior where the nerve could rest. Using our device, we were able to both stimulate and record neural activity successfully,” said Lissandrello. “Ultimately, the nanoclip is a tool which addresses many challenges associated with interfacing with small-diameter nerves in the peripheral nervous system and we hope it will enable others to conduct studies which would not have been previously possible.”

According to White, while this technique may not lend itself to mass-produce large batches of these tools, the fast turnaround time between design, production and implementation made it a great option for conducting science experiments because they happen on a much smaller scale. White will continue to work with Gardner’s research group to speed up the printing process so it could become scalable for manufacturing. She also intends on extending the nanoclip design to include optical sensing, where optical fibers are incorporated into the sensor for use in areas such as optogenetics.

“The feedback from the surgeon about the ease of use was quickly incorporated in the design, which had several iterations. Because we could run through the iterations quickly, it made this a successful experiment,” said White. “It’s a simple thing, but it fulfilled a need to move the science forward and I look forward to more opportunities to collaborate with other faculty researchers in the future.”